Roofing is one of the most critical aspects of any construction project. A well-installed roof protects the building from harsh weather, enhances energy efficiency, and contributes to the overall aesthetic appeal. Achieving a high-quality roof requires precision, skill, and the right tools. This is where roofing machines come into play. These specialized machines streamline installation, improve accuracy, and save both time and labor costs.

What Are Roofing Machines?

Roofing machines are mechanical tools designed to automate and simplify various tasks in the roof installation process. They can handle metal panels, shingles, tiles, and other roofing materials, reducing manual labor and enhancing efficiency. These machines are widely used in both residential and commercial construction projects.

Roofing machines are not a single device but a category that includes a variety of machines tailored to specific tasks. From cutting and shaping metal panels to bending gutters and fastening shingles, roofing machines improve speed, accuracy, and consistency in installation.

Types of Roofing Machines

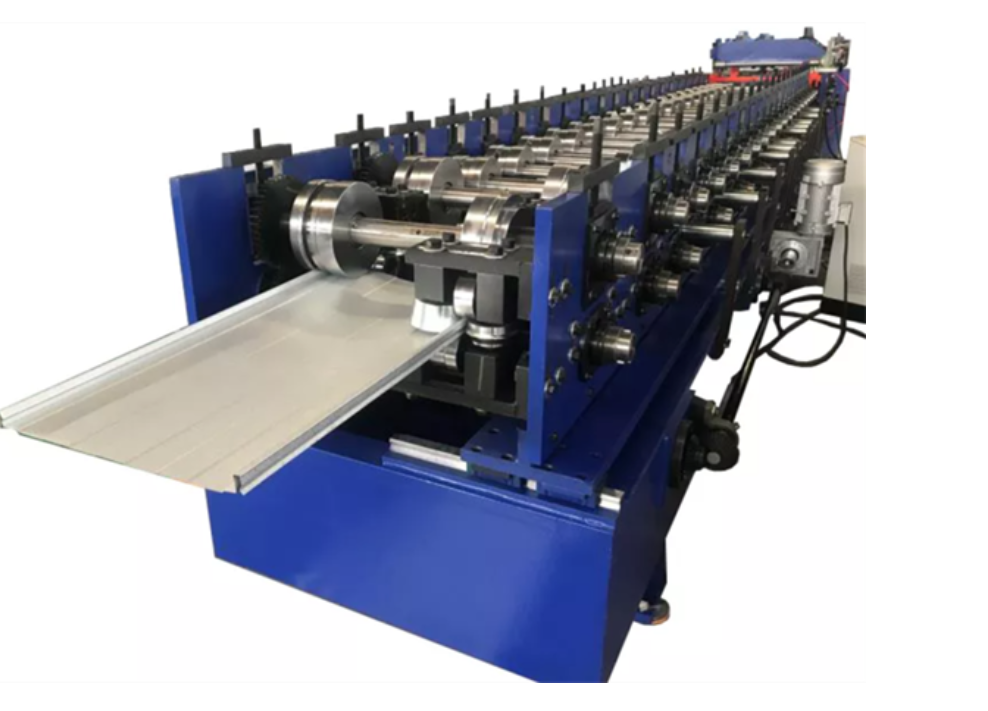

1. Roll Forming Machines

Roll forming machines are primarily used for shaping metal roofing panels. They take flat metal sheets and form them into specific profiles, such as standing seam panels, corrugated sheets, or metal shingles. These machines are essential for contractors who work with metal roofs, as they allow on-site fabrication, reducing transportation costs and material waste.

Benefits:

-

Precise shaping of metal panels

-

On-site customization

-

Reduces material waste

2. Seamers

Seamers are used to interlock standing seam metal panels. By mechanically folding the seams, these machines ensure a tight fit and leak-proof installation. This process enhances the durability and weather resistance of the roof.

Benefits:

-

Creates secure, watertight seams

-

Reduces manual labor

-

Ensures consistent quality across panels

3. Nail Guns and Fastening Machines

Nail guns and other fastening machines are designed to secure shingles, tiles, or metal panels quickly and accurately. These tools are widely used in both residential and commercial roofing projects. They increase installation speed and reduce the risk of uneven fastening, which can compromise the roof’s integrity.

Benefits:

-

Speeds up installation

-

Reduces fatigue from manual nailing

-

Ensures even and secure fastening

4. Cutting Machines

Cutting machines are used to trim roofing materials to the required size and shape. This includes metal shears, tile cutters, and specialized saws for composite materials. Accurate cutting is essential for a clean and professional finish, and these machines minimize errors and material wastage.

Benefits:

-

Precise cutting of roofing materials

-

Reduces material waste

-

Improves overall installation quality

5. Gutter Machines

While primarily used for gutters, many roofing contractors use gutter machines as part of the roofing process. These machines roll-form gutter sections to exact lengths, allowing for a seamless fit and reducing on-site labor.

Benefits:

-

Custom-length gutter fabrication

-

Reduces installation time

-

Enhances water drainage and roof longevity

Advantages of Using Roofing Machines

Increased Efficiency

Roofing machines allow contractors to complete projects much faster than manual methods. Roll forming, cutting, and fastening machines streamline repetitive tasks, enabling crews to cover more ground in less time.

Enhanced Accuracy

Manual roofing can lead to errors in alignment, cutting, or fastening. Roofing machines reduce these errors, ensuring that panels and shingles are installed correctly and securely.

Reduced Labor Costs

By automating time-consuming tasks, roofing machines reduce the need for large crews. Fewer laborers are needed on-site, which translates into lower labor costs for contractors.

Improved Safety

Many roofing machines minimize the physical strain on workers. Nail guns, seamers, and roll formers reduce repetitive motion injuries, while precise cutting and shaping tools reduce the risk of accidents caused by manual cutting.

Consistent Quality

Using machines ensures uniformity across the roof. Each panel, seam, or shingle is installed with the same level of precision, creating a professional and aesthetically pleasing finish.

How Roofing Machines Are Used in Modern Construction

Modern roofing projects, whether residential, commercial, or industrial, rely heavily on these machines to meet tight deadlines and quality standards. Here’s how they are typically used:

-

Pre-Fabrication: Roll forming machines allow contractors to pre-fabricate metal panels on-site. This reduces transportation costs and ensures panels are ready for immediate installation.

-

Fastening: Nail guns and automatic fasteners are used to quickly attach shingles, tiles, or panels to the roof deck.

-

Seaming: Standing seam panels are mechanically seamed for a tight, leak-proof fit.

-

Cutting and Shaping: Specialized cutting machines trim panels and shingles to size, ensuring proper alignment at edges, corners, and roof junctions.

-

Gutter Integration: Gutter machines produce seamless gutter sections that match the roof dimensions, improving water drainage and roof performance.

Key Considerations When Choosing Roofing Machines

Type of Roofing Material

Different machines are required for metal, shingle, tile, or composite roofs. Selecting equipment that is compatible with your material is crucial for efficiency and quality.

Project Size

Large commercial projects may require industrial-grade roll formers and seamers, while smaller residential projects can often be completed with portable and lightweight machines.

Budget

Investing in high-quality roofing machines can reduce long-term labor costs and improve project quality. While upfront costs may be higher, the return on investment through efficiency and reduced waste is significant.

Skill Level

Some machines require specialized training to operate effectively. Contractors should ensure their team is properly trained to maximize the benefits of each machine.

Maintenance

Regular maintenance of roofing machines is essential for longevity and performance. Proper lubrication, cleaning, and calibration prevent breakdowns and ensure consistent results.

Conclusion

Roofing machines are indispensable tools in modern construction. They enhance efficiency, improve accuracy, reduce labor costs, and ensure consistent, high-quality roof installation. From roll formers and seamers to nail guns and cutting machines, each piece of equipment plays a vital role in the roofing process.